VO+ MDO PE Film (Machine Direction Orientation)

VO+ PE voided white films address the conflict between material reduction, performance, and recyclability by combining the benefits of MDO with VO+ technology. This unique proposition is enabling packaging manufacturers and consumer goods companies to develop a new generation of more sustainable products based on:

- Material reduction: Low density & downgauging

- Performance: Improved puncture, toughness, and high opacity without TiO2

- Recycling: VO+ enables improved recyclability over traditional pigmented films

A new generation of flexible packaging

VO+ films are relevant to a range of products, including flexible packaging, industrial and agricultural applications. Some of our most advanced film structures and packaging applications include:

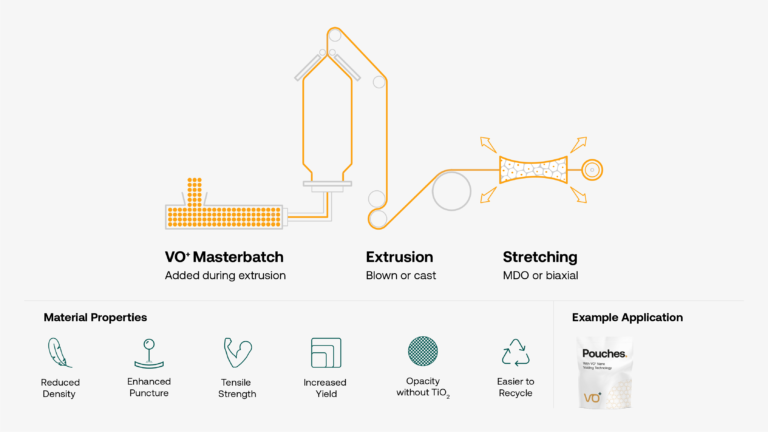

Using VO+ PE masterbatch in film

We supply VO+ PE “masterbatch” to film manufacturers in a resin pellet form. The masterbatch can then be processed using conventional blown or cast film extrusion equipment. After extrusion, the film must be stretched to form the voided structure. Typically, this is achieved with machine direction orientation (MDO), but transverse (TDO) or biaxial orientation processes are also possible.

The voided structure reduces the film density and also diffracts light which creates an opaque white film without the need for pigments such as TiO2. This offers two advantages for recycling VO+ films:

-

- Unlike pigmented films, VO+ white films become translucent when reprocessed enabling them to be recycled in clear waste streams without causing color contamination

- VO+ PE films always have density below 1g/cm3 and are an excellent solution for creating super high opacity films. In comparison, films loaded with high levels of TiO2 are difficult to recycle because the TiO2 increases the film density above 1g/cm3, and this prevents the film from floating in water-based separation processes.

VO+ Blown Film to inline MDO

VO+ PE films: 35% material reduction without compromising performance

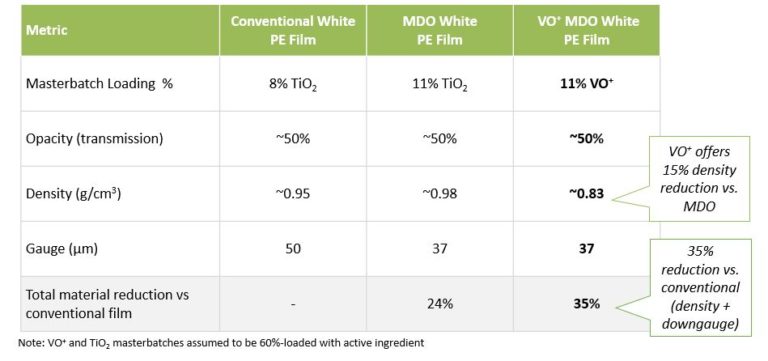

The table below shows the material reduction benefit of VO+ MDO PE white film vs a conventional white film and an MDO white film which both use TiO2 to achieve opacity.

Illustrative Example